Expert Assistance for Your Mechanical Engineering Projects

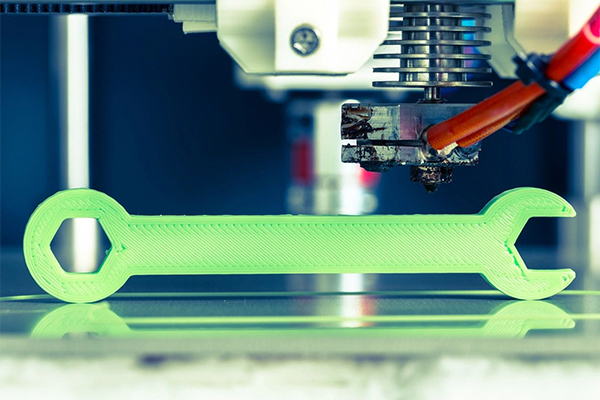

3D Scanning and Printing

We provide high-quality and cost-effective 3D scanning services. Using high-precision laser scanners, we can capture millions of data points. If needed, our experienced engineers can take the data and reverse engineer it.

As a result, we are able to provide you with a solid Computer-Aided Design (CAD) file. Whether you need a 3D scan for your hobby or your company needs it for manufacturing and design, we are here to help.

Design of Complex Assemblies

Teckna 3D can develop your design from concept through development and production. We regularly work with customers from the early stages of product definition to integrate mechanical function and physical form into a complete assembly ready for production.

Injection Molded Plastics

Teckna 3D has a proven track record of successful commercial designs created for quantities from 500 to 1,000,000 parts per year. Applications include consumer products, computers, and medical devices. Teckna 3D is experienced in the use of a range of material applications, including high-strength glass-filled resins, elastomeric overmolding, and transparent materials.

Sheet Metal, Castings, and Machined Parts

Teckna 3D has a long and successful history of creating metal parts made from aluminum, steel, zinc, and other metals and experienced in applications from specialty medical devices through mass-produced industrial-grade products and fabrication methods including sheet metal, castings of all sorts, machined parts, forgings, and welded structures.

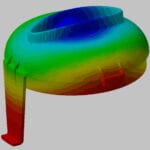

Reverse Engineering/

Complex Surfacing

Teckna 3D uses the Next Engine Laser Scanner for reverse engineering and development of ergonomic, anatomic, and aerodynamic surfaces. Teckna works with industrial designers to develop producible designs that sell. The product at the left sold over 1,000,000 units.

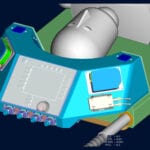

Medical Device Development

Teckna 3D has experience in developing the physical design of medical devices. This includes chassis design, component layouts, plastic skins, integration of connectors, and routing of cables. Teckna has experience with FEA analysis of medical-grade plastic components in demanding applications.

Industrial Design, Concept Development, and Complex Machinery Layouts

Teckna 3D can work with your team to take your project from back of the envelope concept sketches to working complex machinery layouts. This wind turbine design appeared on the cover of "Windpower Engineering Magazine."